When you take a generic pill, you expect it to work just like the brand-name version. But behind that simple tablet or injection is a highly controlled environment-cleanroom standards-that make this possible. These aren’t just guidelines. They’re strict, science-backed rules that prevent contamination, ensure safety, and guarantee that your generic drug does exactly what it’s supposed to do.

Why Cleanrooms Matter for Generic Drugs

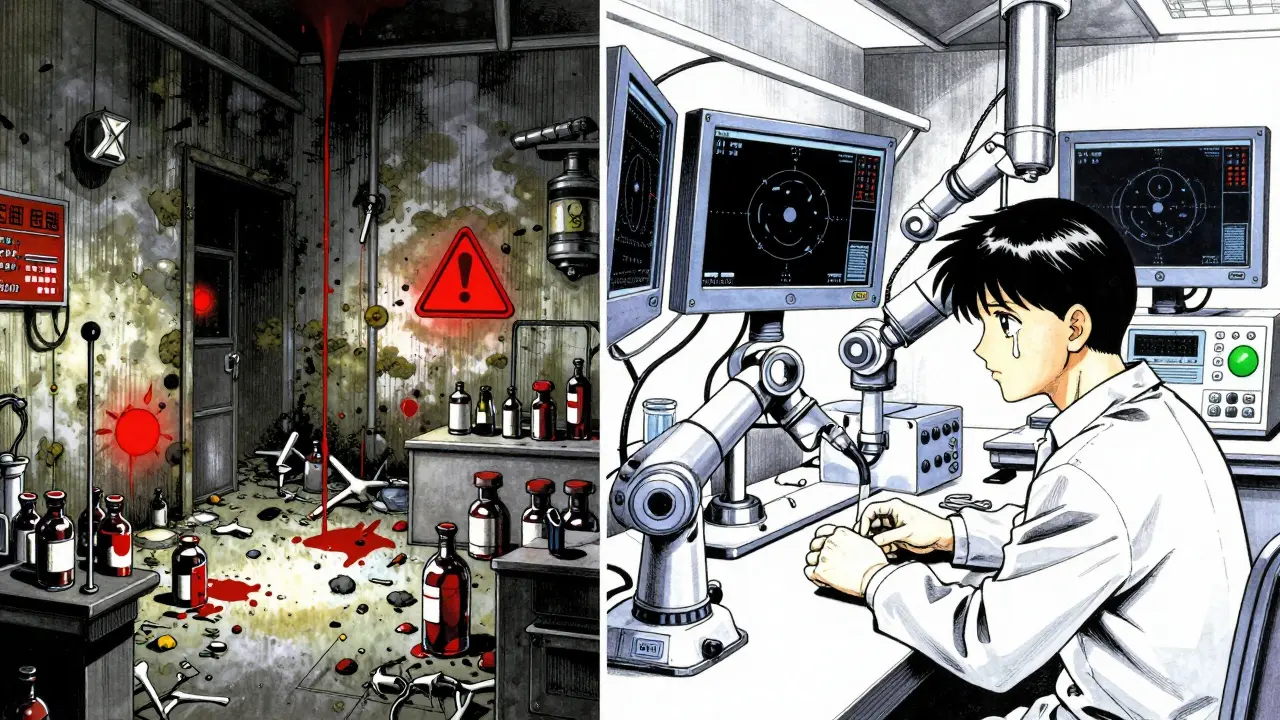

Generic drugs aren’t cheaper because they’re lower quality. They’re cheaper because they don’t need to repeat expensive clinical trials. But they must prove they’re bioequivalent to the original drug. That means the same active ingredient, in the same strength, delivered the same way, with the same effect in your body. Here’s the catch: even tiny amounts of dust, microbes, or foreign particles can change how a drug behaves. A single airborne particle can ruin a sterile injection. A spike in humidity can cause a tablet to degrade. That’s why cleanrooms exist-not to impress auditors, but to stop recalls, infections, and deaths. The 2012 New England Compounding Center outbreak, which killed 64 people and sickened over 750 from contaminated steroid injections, was caused by filthy conditions. No cleanroom controls. No oversight. That tragedy changed everything. Today, every generic manufacturer must meet the same environmental standards as the innovator company-even if their profit margin is half.The Four Levels of Cleanrooms: What Each Grade Means

Cleanrooms aren’t all the same. They’re divided into four grades, each with exact particle and microbial limits. These are based on ISO 14644-1, the global standard for air cleanliness.- Grade A (ISO Class 5): Used for sterile filling and critical processes. No more than 3,520 particles ≥0.5μm per cubic meter. Think of it as a surgical suite for drugs. Air moves in straight, laminar flows at 0.36-0.54 m/s. Every breath, every glove movement, is monitored.

- Grade B (ISO Class 5 at rest, ISO Class 7 operational): The background environment for Grade A. It’s where you prepare solutions and load equipment. At rest, it’s as clean as Grade A. During operations, it allows up to 3.5 million particles. Continuous monitoring is required.

- Grade C (ISO Class 7 at rest, ISO Class 8 operational): Used for less critical steps like weighing ingredients or packaging non-sterile products. Allows up to 3.5 million particles at rest and 35 million during operations. Minimum 20 air changes per hour.

- Grade D (ISO Class 8 at rest): The lowest tier. Used for storage, packaging, and preparation areas. No operational limit-just 35 million particles at rest. Minimum 10 air changes per hour.

Regulations: FDA vs. EU vs. Global Standards

The U.S. FDA doesn’t use the terms “Grade A” or “ISO Class 5.” Instead, it relies on cGMP rules under 21 CFR Parts 210 and 211. It says facilities must be designed to prevent contamination-but doesn’t spell out particle counts. The EU, through EudraLex Volume 4 and Annex 1 (updated August 2023), is far more specific. It ties every grade directly to ISO numbers. This creates a challenge for global manufacturers. A company making a generic drug for both the U.S. and Europe must meet the stricter EU rules to avoid having products rejected at the border. The FDA has signaled it will align with Annex 1, but hasn’t formally adopted it yet. Then there’s USP Chapter <797>, which governs compounding pharmacies. It allows ISO Class 7 buffer rooms for sterile compounding. That’s one level below what’s required for manufacturing Grade A injectables. The difference? One is for pharmacists mixing doses in a hospital. The other is for factories producing millions of doses for public use.

Costs and Challenges for Generic Manufacturers

Building a Grade A cleanroom costs $250-$500 per square foot. For a 5,000-square-foot facility? That’s $1.25 million to $2.5 million before equipment, validation, or staff training. A Pfizer facility spent $2.3 million upgrading from Grade C to Grade B for a generic cancer drug. The payoff? They prevented 17 out-of-spec batches a year-worth $8.5 million in lost product. But small manufacturers don’t have that kind of cash. One Reddit user, from a small generic maker, said maintaining Grade A for a $0.50-per-unit heparin syringe made the business unprofitable after the third FDA inspection flagged minor particle spikes. That’s the reality: cleanrooms are a survival tool for big players, but a death sentence for some small ones. Personnel are the biggest source of contamination. Gowning procedures take 40-60 hours to train. Even then, people move, talk, sneeze. Real-time particle monitors cost $50,000-$100,000 per room just to catch those errors.Success Stories and Cautionary Tales

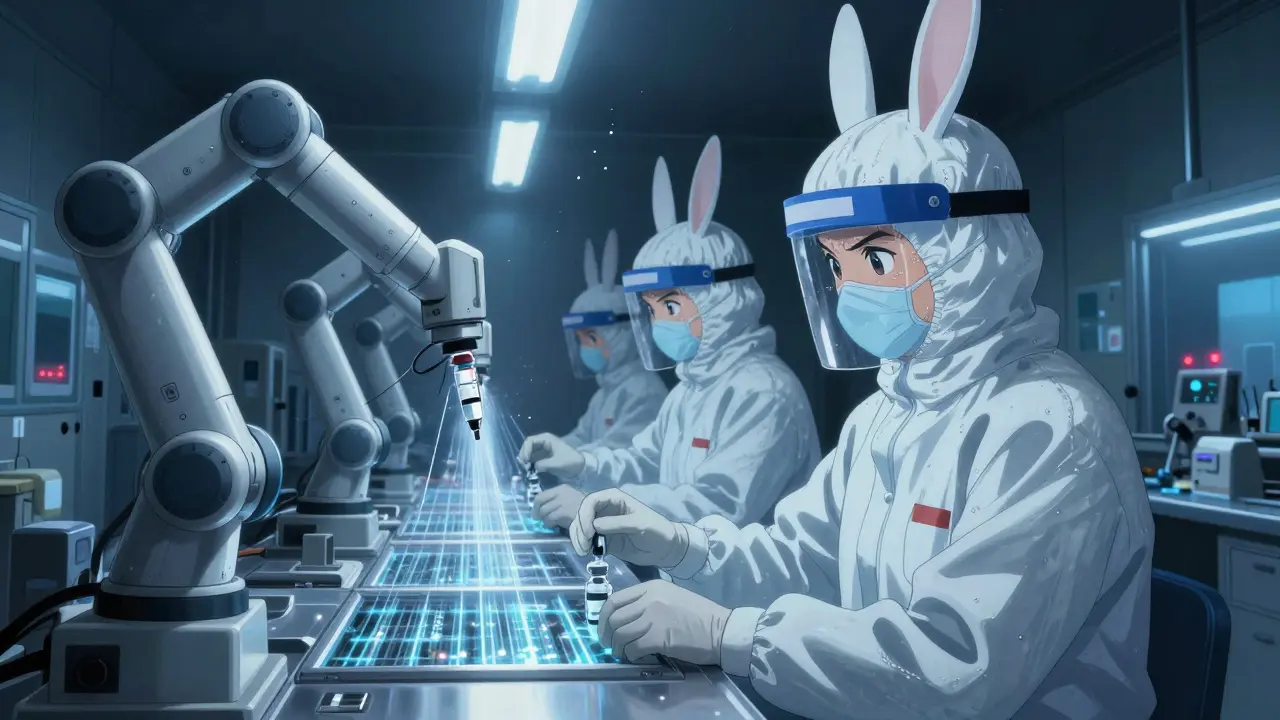

Teva’s generic version of Copaxone, a multiple sclerosis drug, was rejected twice because of contamination in Grade A areas. They installed isolator technology-sealed, robotic systems that handle sterile filling without human contact. Contamination events dropped from 12 per year to just 2. Approval followed. Aurobindo Pharma wasn’t so lucky. In 2022, the FDA issued a consent decree after finding inadequate Grade B monitoring. Over $137 million in sterile injectables were recalled. The company lost market share, faced lawsuits, and had to rebuild its entire quality system. These aren’t abstract risks. They’re financial, legal, and moral failures.

What’s Changing in 2025 and Beyond

The EU’s 2023 Annex 1 revision requires continuous monitoring-no more weekly checks. Sensors now run 24/7, sending alerts if particle levels rise. The FDA is expected to follow. New technologies are helping. Robotics are taking over manual tasks. AI monitors airflow patterns and predicts contamination risks before they happen. McKinsey projects automation will cut cleanroom operating costs by 25-30% by 2028. But new drugs are getting harder. Biosimilars, inhalers, complex injectables-they all need tighter controls than standard cleanrooms were designed for. The FDA predicts 50% of new generic applications by 2025 will need Grade A/B environments, up from 35% in 2022. Meanwhile, emerging markets like India are spending $4.2 million per facility to meet Annex 1 standards-$1.4 million more than U.S. companies, thanks to weaker infrastructure. Global supply chains depend on these manufacturers. If they can’t keep up, drug shortages will follow.What You Can Do: Understanding Your Generic Drugs

You don’t need to build a cleanroom. But you can ask questions. When you get a generic drug, know it’s held to the same standard as the brand. If your generic suddenly looks different, or you hear about a recall, it’s not because the drug is “weaker.” It’s because the environment it was made in didn’t meet the rules. The FDA’s website lists warning letters and recalls. If a generic drug maker has multiple citations for environmental violations, that’s a red flag. You have the right to safe medicine-no matter who made it.Resources for Manufacturers

For those running these facilities, help exists:- Free FDA cGMP training modules

- ISPE’s Good Practice Guide: HVAC

- PDA Technical Reports 14, 22, and 45 on sterile processing

- WHO Technical Report Series No. 961 on environmental controls

What happens if a generic drug manufacturer doesn’t meet cleanroom standards?

If a facility fails to meet cleanroom standards, the FDA or EMA can issue a Form 483 (inspectional observations), a warning letter, or even an import alert blocking shipments. In severe cases, products are recalled-sometimes millions of units-and the company may face consent decrees, fines, or shutdowns. In 2022, 63% of all FDA warning letters were for cGMP violations, most tied to environmental controls.

Are cleanroom standards the same for oral pills and injectables?

No. Injectable drugs, eye drops, and other sterile products require Grade A or B environments because they go directly into the bloodstream. Oral pills, like tablets or capsules, typically only need Grade C or D, since the digestive system acts as a barrier. However, even for oral products, cross-contamination from other drugs or allergens must be prevented, so cleanrooms are still required-but less stringent.

Why do cleanroom standards keep changing?

Standards evolve because science improves. We now know that even invisible particles and subtle airflow disruptions can cause contamination. The 2023 EU Annex 1 update, for example, added requirements for continuous monitoring and risk-based assessments. It’s not about being stricter for the sake of it-it’s about catching problems before they reach patients.

Can a generic drug be approved without a cleanroom?

No. All pharmaceutical manufacturing, including generics, must occur in a controlled environment. Even non-sterile products require cleanrooms to prevent contamination from dust, microbes, or cross-contamination with other drugs. The level of control varies by product type, but no facility can legally produce drugs in an uncontrolled space.

Do cleanroom standards apply to over-the-counter (OTC) drugs too?

Yes. All drugs regulated by the FDA-including OTC medications like pain relievers or antacids-must be manufactured under cGMP rules. While OTC products don’t need Grade A or B cleanrooms, they still require controlled environments with proper filtration, personnel training, and monitoring to ensure safety and consistency.

Elaine Douglass

December 20, 2025 at 19:23

I never thought about how much goes into a generic pill

Now I just feel grateful someone’s watching over it

My grandma takes six of these a day and I sleep better knowing it’s safe