FDA Deficiency Letters: What They Mean for Generic Drugs and Patient Safety

When the FDA deficiency letters, official notices from the U.S. Food and Drug Administration warning drug manufacturers of serious compliance issues. These letters are not fines—they’re red flags that something in the manufacturing process is broken, and it could put patients at risk. They’re the FDA’s way of saying: "Your drug isn’t safe yet, and we won’t let it hit the market until you fix this." Most of these letters target generic drug makers, especially those overseas, where quality control is inconsistent. You might not hear about them directly, but they’re behind every recall, every shortage, and every time a generic you’ve been taking suddenly stops working the same way.

FDA deficiency letters often point to problems like nitrosamine contamination, the presence of cancer-causing impurities in drugs like ranitidine and metformin, or poor data integrity—where labs fake test results to make drugs look safer than they are. These aren’t rare mistakes. Since 2018, over 500 recalls have been linked to these issues. Another common finding? Chinese generic production, the source of 80% of the world’s active drug ingredients, where inspections regularly uncover unclean facilities and falsified records. It’s not that all generics are unsafe—it’s that some manufacturers cut corners, and the FDA catches them before patients get hurt.

But here’s the real problem: FDA safety alerts, public warnings about dangerous drugs often come months or even years after the deficiency letter is sent. That’s because labeling rules for generics don’t always update automatically. So you might be taking a drug that the FDA already flagged as risky, but your prescription label still says it’s fine. That’s why knowing about deficiency letters matters—you can’t always rely on the system to warn you.

These letters also explain why some generics fail. If a manufacturer changes the process after getting approval—say, switches suppliers or skips a purification step—the drug might still pass bioequivalence tests but behave differently in your body. That’s what leads to therapeutic failures, when a generic doesn’t control your condition like the brand did. It’s not your fault. It’s not your body. It’s a manufacturing issue the FDA caught in a deficiency letter but didn’t stop from reaching shelves.

What you’ll find in the posts below isn’t just a list of articles—it’s a map of the hidden risks in your medicine cabinet. From how nitrosamines slipped into common pills, to why your insurance pushes generics even when they’ve been flagged, to how states are trying to fix this mess. You’ll learn how to spot when a generic might be risky, what to ask your pharmacist, and how to protect yourself when the system isn’t working the way it should. This isn’t theory. These are real drugs, real recalls, and real people who got hurt because no one told them what the FDA already knew.

Deficiency Letters in Generic Drug Applications: Common FDA Findings and How to Avoid Them

Deficiency letters from the FDA are the main reason generic drug applications get rejected. Learn the top 5 reasons they’re issued, how to avoid them, and what’s changing at the FDA to speed up approvals.

About

Medications

Latest Posts

Monoclonal Antibody Biosimilars: Examples and Clinical Uses

By Orion Kingsworth Jan 31, 2026

Diltiazem vs Alternatives: A Comprehensive Comparison

By Orion Kingsworth Sep 28, 2025

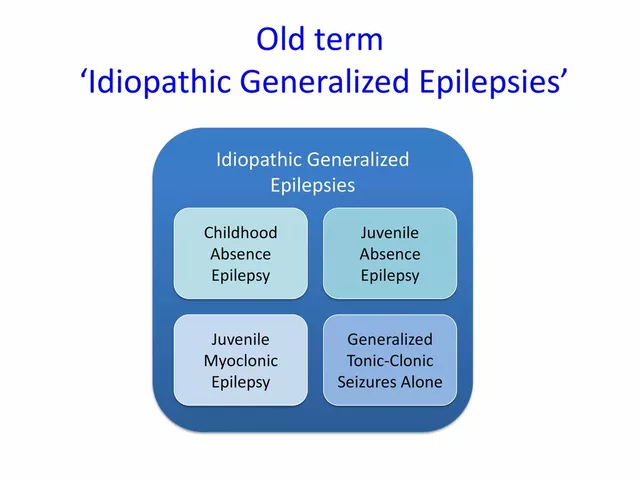

Myoclonic Seizures and Advocacy: How to Make a Difference

By Orion Kingsworth May 5, 2023