Order Fulfillment in Pharmaceuticals: How Medications Reach You Safely

When you order a prescription or over-the-counter drug online, order fulfillment, the end-to-end process of receiving, processing, packing, and shipping medication to the customer. It's not just about sending a box—it's a tightly controlled system that keeps drugs safe, legal, and effective. This process involves pharmacies, distributors, manufacturers, and regulators all working together. If any step fails, you could get the wrong pill, an expired dose, or even a contaminated product. That’s why order fulfillment in pharmaceuticals isn’t like ordering a book or a pair of shoes.

pharmaceutical supply chain, the network of organizations and activities involved in producing and delivering medications is one of the most complex in the world. It starts with raw ingredients—often made in China or India—then moves to labs for formulation, then to warehouses that must meet strict temperature and humidity rules. From there, it goes to pharmacies or online retailers who verify your prescription, check for interactions, and finally ship it. Any break in this chain—like a mislabeled batch or a delayed FDA inspection—can lead to recalls, like the nitrosamine contamination, a dangerous impurity found in some blood pressure and diabetes medications that triggered over 500 recalls since 2018.

Order fulfillment also has to handle the difference between brand-name drugs and generics. A generic drug delivery, the process of distributing FDA-approved copies of brand-name medications sounds simple, but it’s not. Some generics fail because of poor manufacturing, poor storage, or even incorrect labeling. That’s why some patients report that their generic blood pressure pill doesn’t work the same as the brand. The system isn’t broken—it’s just under pressure. States are trying to fix it with generic prescribing incentives, policies that encourage doctors to choose lower-cost generics, but without better oversight, cost savings can come at the cost of safety.

And it’s not just about getting the right drug—it’s about getting it at the right time. If your insulin or heart medication is delayed because of a shipping error or customs hold, it’s not just inconvenient—it’s dangerous. That’s why the best order fulfillment systems track every box, log every temperature, and verify every signature. They don’t just ship pills—they protect lives.

Below, you’ll find real-world examples of how things can go wrong—and right—in pharmaceutical order fulfillment. From how Chinese manufacturers affect your meds to why some generics don’t work, these posts show you the hidden steps behind every pill you take. You won’t just learn how your medicine gets to you—you’ll learn how to spot when something’s off.

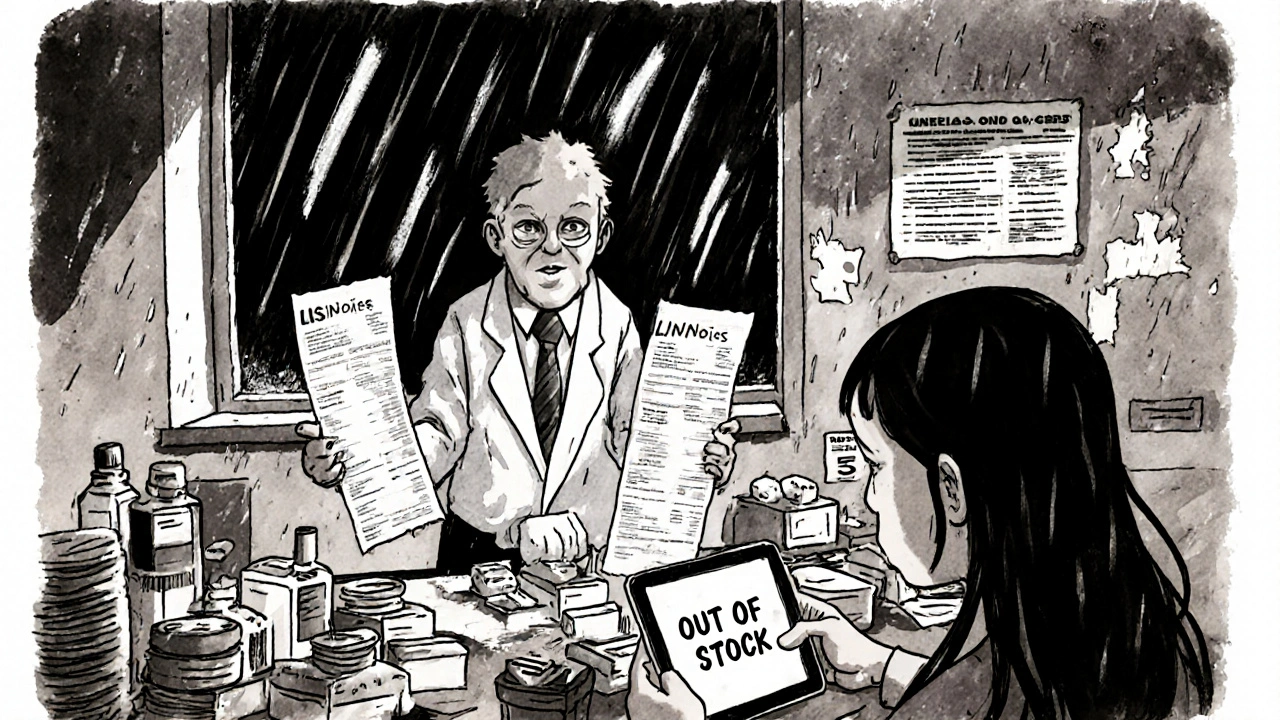

How to Handle Partial Fills and Back-Orders Without Errors in Pharmacy Operations

Learn how to manage partial fills and back-orders in pharmacies without risking dispensing errors. Real-world strategies for inventory tracking, billing, communication, and staff training to keep patients safe and satisfied.

About

Online Pharmacies

Latest Posts

Diagnosing Central Cranial Diabetes Insipidus: Tests and Procedures

By Orion Kingsworth Jul 26, 2023

Buy Cheap Generic Effexor Online - Safe Guide & Top Pharmacy Picks

By Orion Kingsworth Oct 5, 2025

Chronic Back Pain: How Physical Therapy, Medications, and Self-Management Work Together

By Orion Kingsworth Jan 18, 2026