Pharmacy Inventory: What’s in Stock and Why It Matters for Your Health

When you walk into a pharmacy, what you see on the shelf is just the tip of a much larger system called pharmacy inventory, the complete collection of medications and supplies a pharmacy holds to meet patient needs. Also known as pharmaceutical stock, it’s not just about having enough pills—it’s about having the right ones, at the right time, and without hidden risks. Every bottle of antibiotics, every generic blood pressure pill, every inhaler you pick up depends on this invisible network of ordering, storage, and quality control.

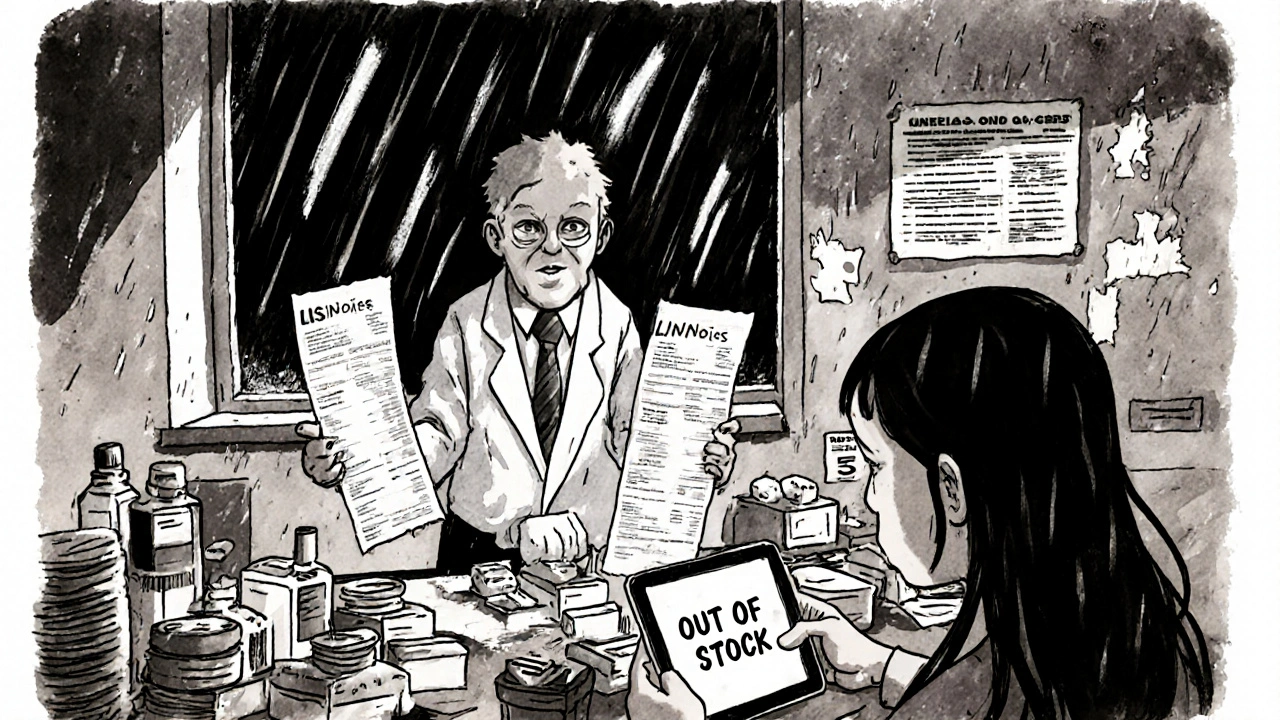

Generic drugs, affordable copies of brand-name medications approved by the FDA. Also known as generic medication, they make up over 90% of prescriptions in the U.S. But their availability isn’t guaranteed. Supply chain problems, manufacturing failures, or raw material shortages can suddenly wipe out a common drug from shelves. That’s not a glitch—it’s a pattern. Since 2018, over 500 drugs have been recalled due to contamination like nitrosamines, and many more have vanished because a single factory in China—responsible for 80% of the world’s active ingredients—got shut down for poor quality control. When a pharmacy’s inventory runs low on a key drug, patients don’t just wait longer. They get switched to alternatives that might not work as well, or worse, cause side effects.

Drug supply chain, the complex path from raw chemical production to your medicine cabinet. Also known as pharmaceutical distribution network, it’s full of weak links. A batch of pills made in India, shipped to a U.S. distributor, then sent to your local pharmacy might look identical to the brand version—but if the manufacturer skipped quality tests or falsified records, you could be getting something unsafe. Authorized generics, which are made by the original brand company, often have fewer risks because they come from the same factory. But most pharmacies stock cheaper, unaffiliated generics because of cost pressures from insurers and state policies pushing generic substitution. That’s why some people report their generic blood pressure pill doesn’t work like it used to—or why a new batch of antidepressant causes weird side effects. It’s not your body changing. It’s the inventory changing under the label.

Pharmacy inventory isn’t just a behind-the-scenes operation. It’s tied to your daily health. If your asthma inhaler runs out and the replacement isn’t in stock, you risk a flare-up. If your thyroid med switches manufacturers without warning, your dose might be off. If a new FDA alert comes out about contamination in a common generic, your pharmacist might not know until it’s too late. The system is reactive, not proactive. And patients pay the price.

Below, you’ll find real stories and data on what’s gone wrong—and what’s being done to fix it. From nitrosamine recalls to Chinese manufacturing flaws, from authorized generics that actually match the brand to policies that force pharmacies to stock cheaper, riskier options—you’ll see how inventory decisions directly impact safety, cost, and outcomes. This isn’t theory. It’s what’s on the shelf next to you.

How to Handle Partial Fills and Back-Orders Without Errors in Pharmacy Operations

Learn how to manage partial fills and back-orders in pharmacies without risking dispensing errors. Real-world strategies for inventory tracking, billing, communication, and staff training to keep patients safe and satisfied.

About

Online Pharmacies

Latest Posts

Nitrosamine Contamination in Generic Drugs: Recent Recalls and Regulatory Shifts

By Orion Kingsworth Nov 17, 2025

Albuterol Inhaler Cleaning Guide: Proper Maintenance Steps

By Orion Kingsworth Oct 25, 2025

How to Read OTC Drug Facts Labels Correctly and Confidently

By Orion Kingsworth Jan 26, 2026